Introduction to Hot Vulcanization Joint Materials for Coal Mine Conveyor Belts

2025-06-13 10:18:28Hot vulcanization jointing has become a common method for coal mine conveyor belt joints due to its excellent connection strength and service life. Among these, suitable joint materials are particularly important. Here are several high-strength belt joint adhesives introduced for you:

DG668 Hot Vulcanization Adhesive: Ultra-Strong Viscosity for Stable Connection

DG668 hot vulcanization adhesive is a high-performance glue specially developed for hot vulcanization joints of conveyor belts. With extremely high bonding strength, it tightly connects all parts of the conveyor belt to form a solid whole, significantly reducing the risk of cracking and delamination at the joint. In the complex transportation environment of coal mines, where materials like coal exert strong impact on the conveyor belt, joints made with DG668 can withstand long-term high-intensity friction and impact, ensuring stable operation of the conveyor belt.

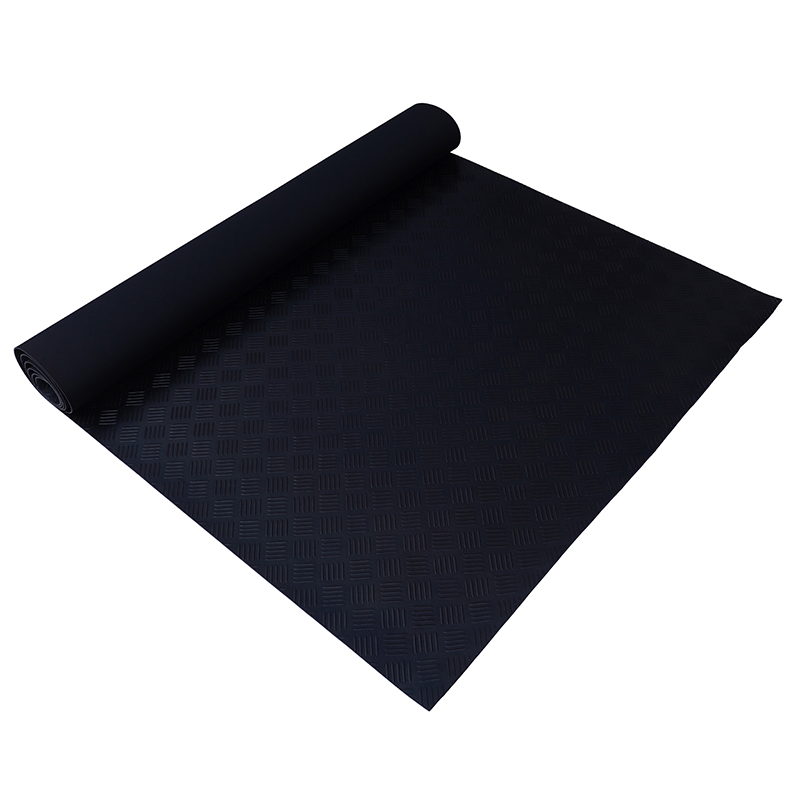

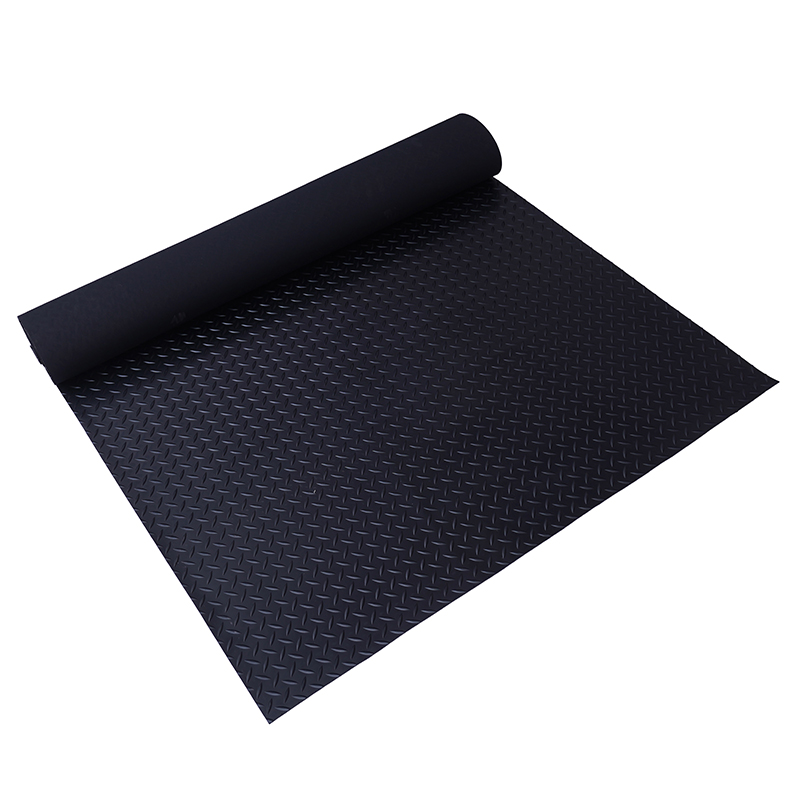

Picozen Series Unvulcanized Core Rubber: Reinforcing Structure and Enhancing Toughness

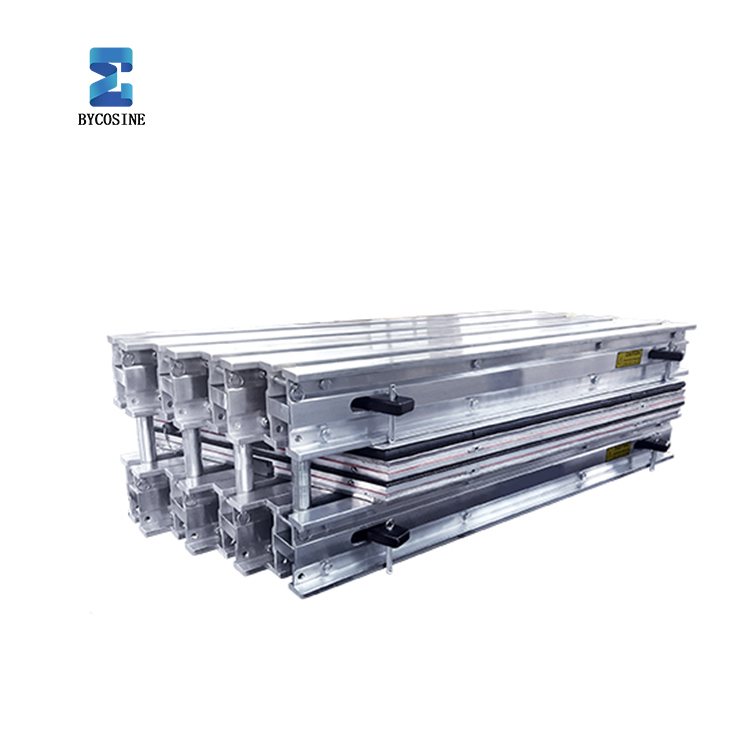

The Picozen series unvulcanized core rubber serves as the "backbone" of conveyor belt joints. It fills the internal structure of the conveyor belt, enhances the bonding force between core layers, and improves the overall toughness and tear resistance of the belt. As coal mine conveyor belts carry heavy materials with many edges and corners, the unvulcanized core rubber can effectively disperse stress, avoiding belt damage caused by excessive local stress and extending the service life of the conveyor belt.

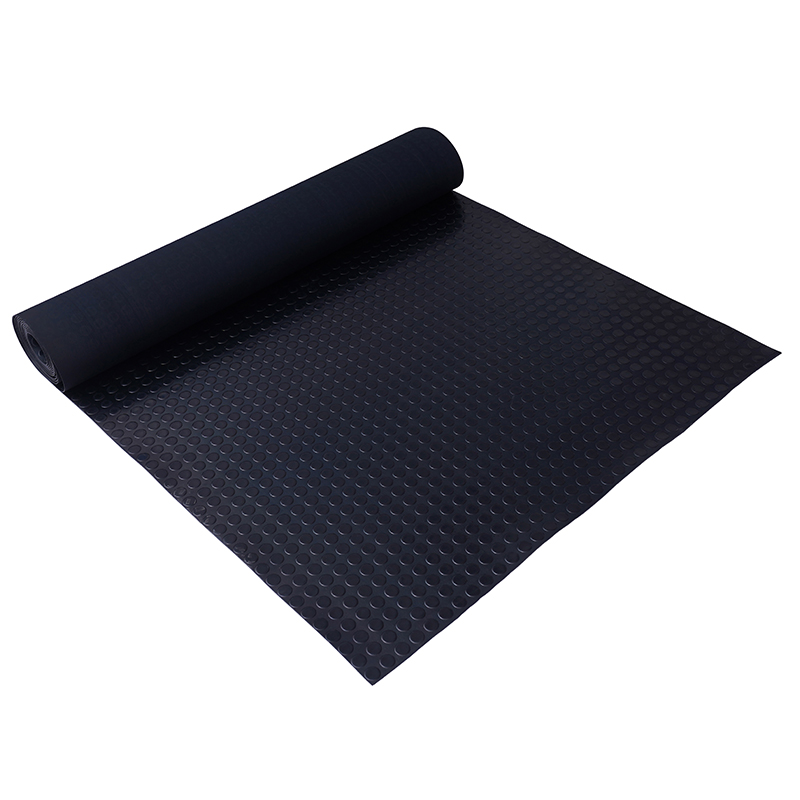

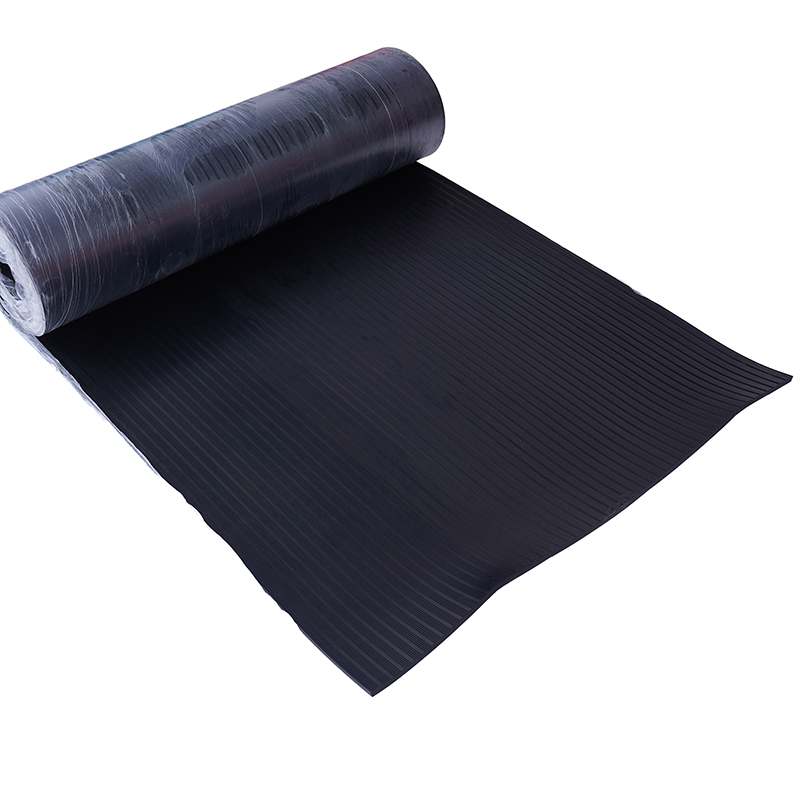

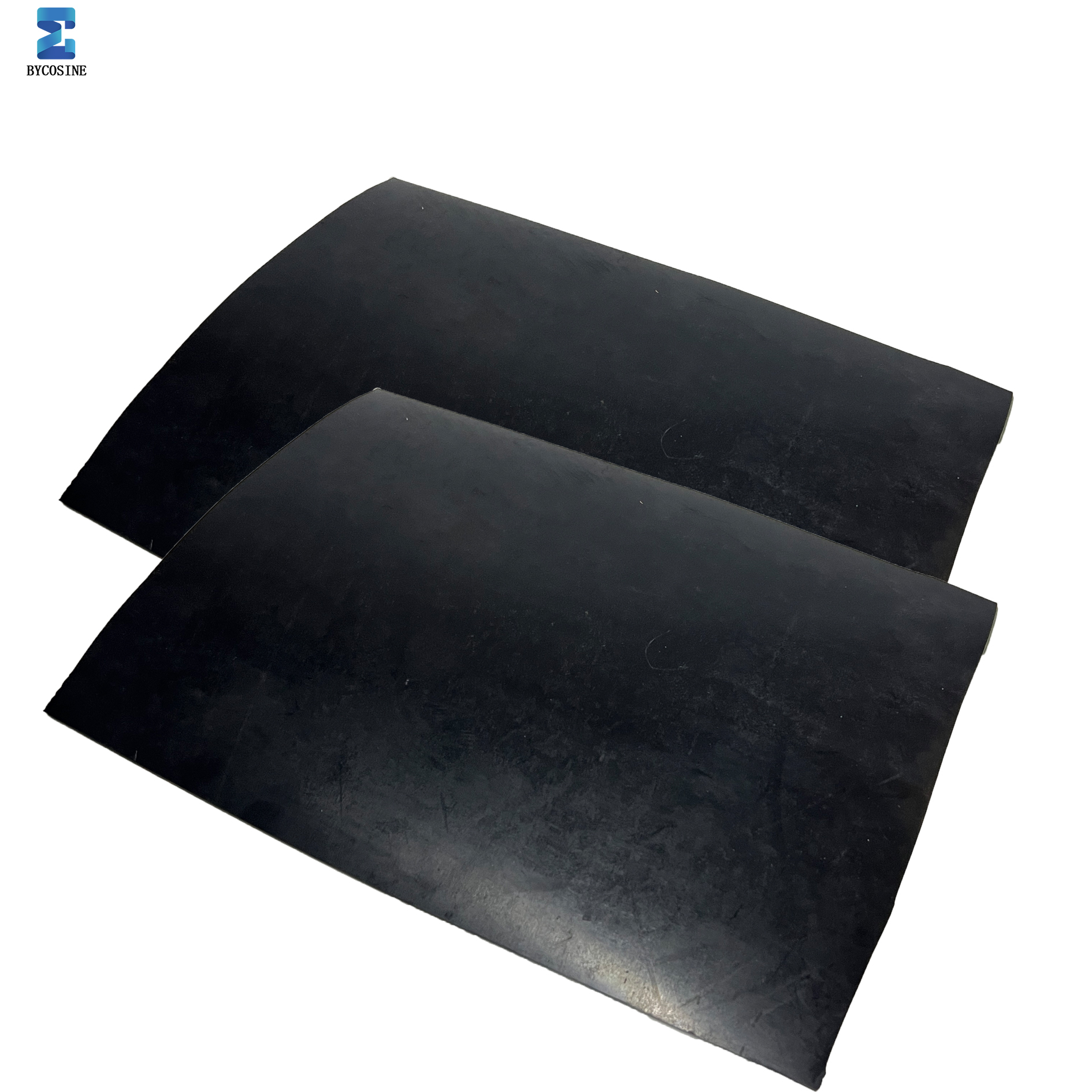

Picozen Series Unvulcanized Surface Rubber: Wear-Resistant Protection Against Erosion

The Picozen series unvulcanized surface rubber is mainly used on the conveyor belt surface to provide a wear-resistant protective layer. In the humid underground environment of coal mines, coal may contain corrosive substances. The unvulcanized surface rubber can resist these erosions, reduce surface wear of the conveyor belt, and prevent material adhesion, ensuring smooth transportation.

Optimal Performance When Used in Combination

Using DG668 hot vulcanization adhesive in conjunction with Picozen series unvulcanized core rubber and surface rubber can fully leverage their respective advantages. Through the hot vulcanization process, the three materials work together to create conveyor belt joints with high strength, wear resistance, and corrosion resistance, meeting the high-intensity and long-term transportation requirements of coal mines.

In conclusion, for the selection of hot vulcanization joint materials for coal mine conveyor belts, DG668 hot vulcanization adhesive combined with Picozen series unvulcanized core rubber and surface rubber is a trustworthy combination. They can effectively improve the quality of conveyor belt joints and ensure safe and efficient production transportation in coal mines.

.jpg)

.png)