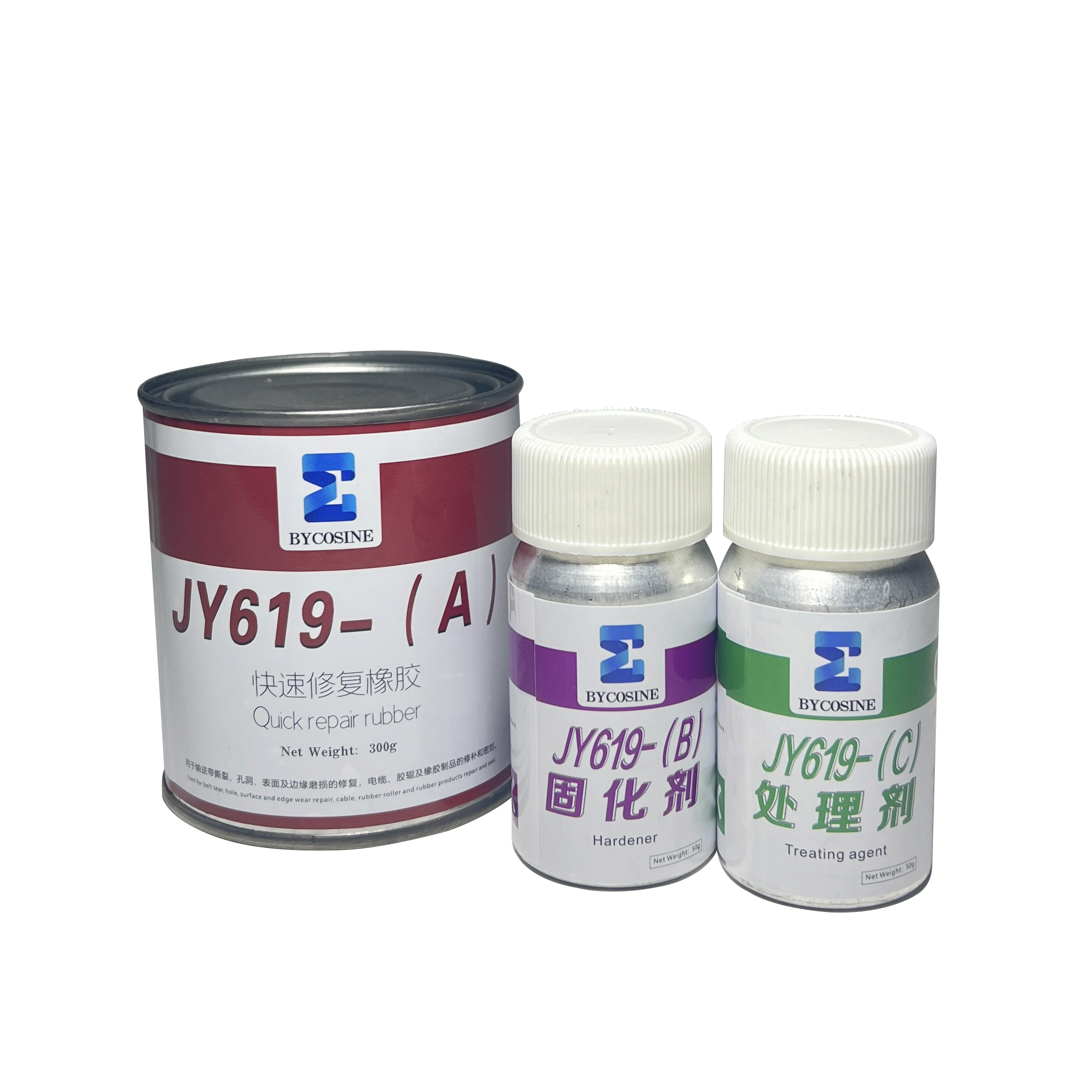

Review of Effective Cold Glue Bonding Adhesives for Drum Rubber Lining

2025-06-13 10:47:36In the process of cold glue bonding for drum rubber lining, the selection of adhesive is crucial as it directly affects the quality of the lining and the performance of the drum. Today, we will review some effective cold glue bonding adhesives for drums, with a focus on recommending the KN373 cold vulcanization adhesive.

I. Powerful Performance of KN373 Cold Vulcanization Adhesive

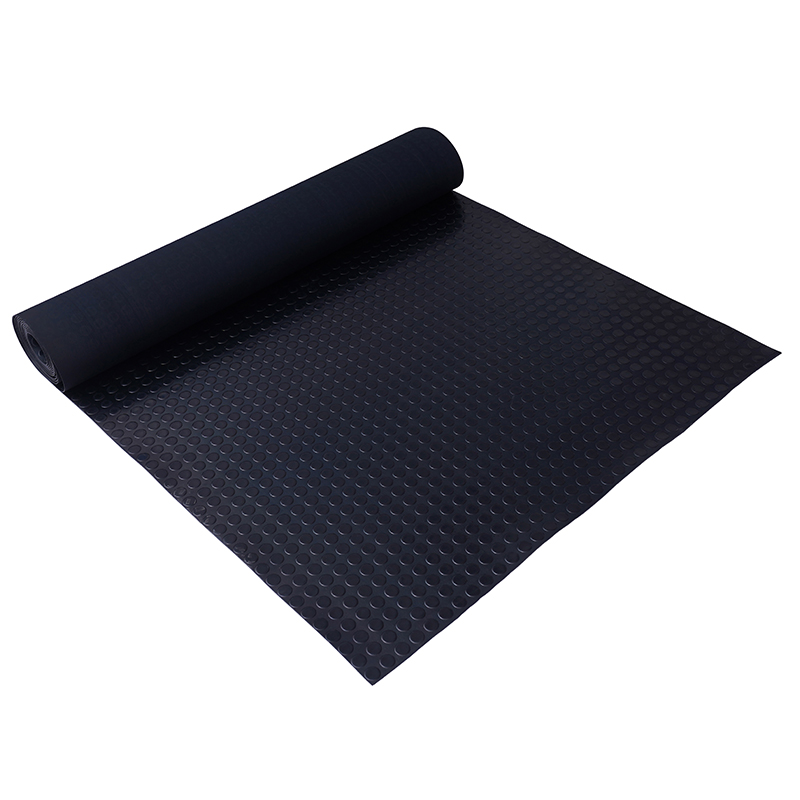

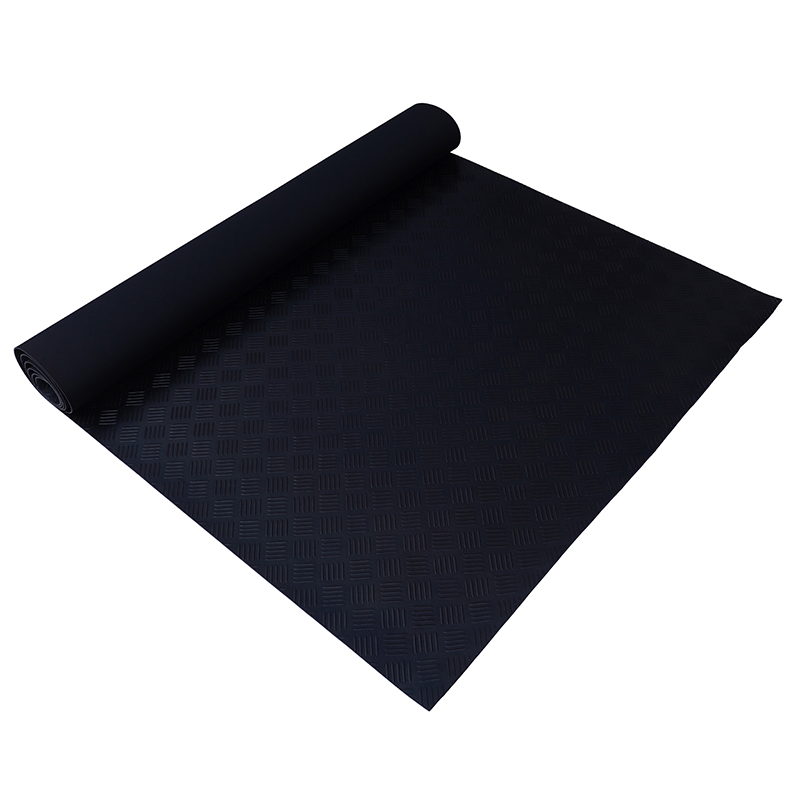

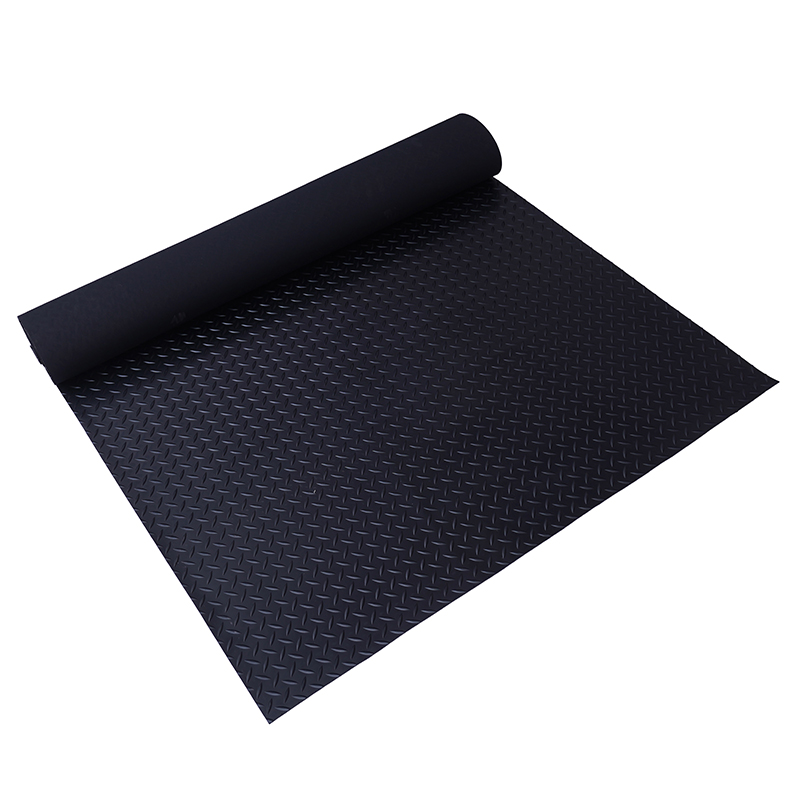

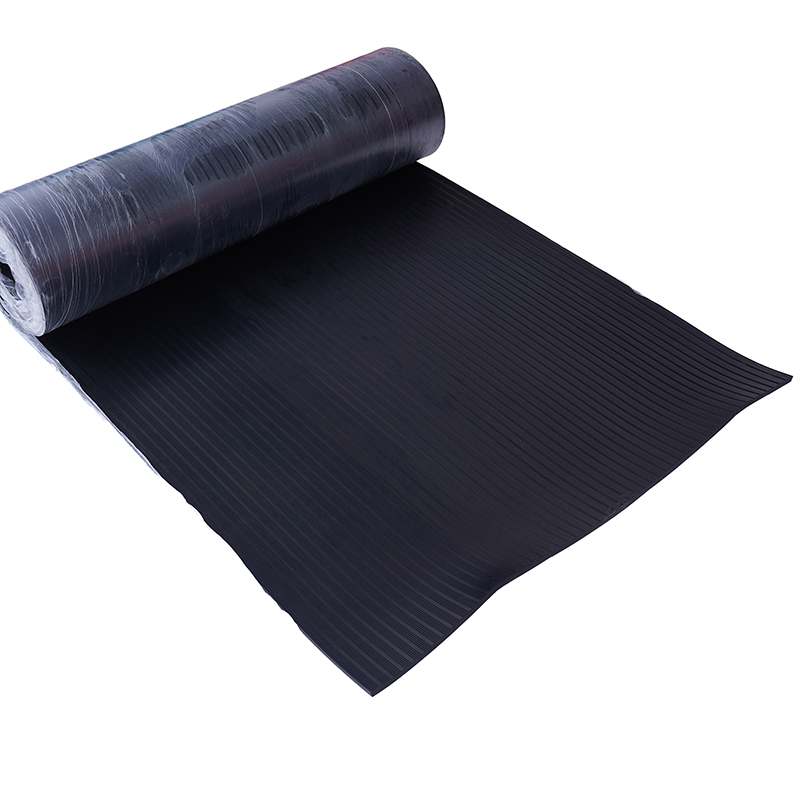

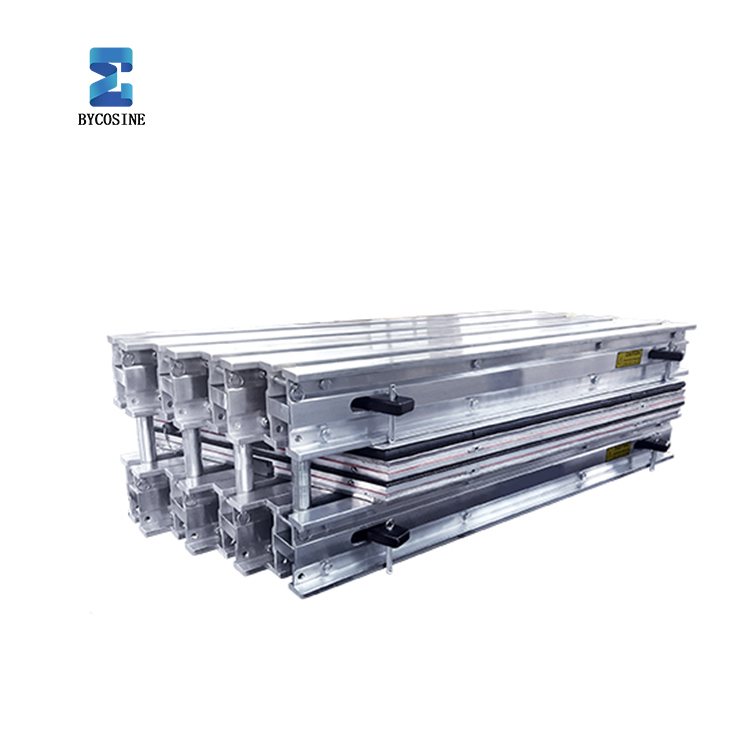

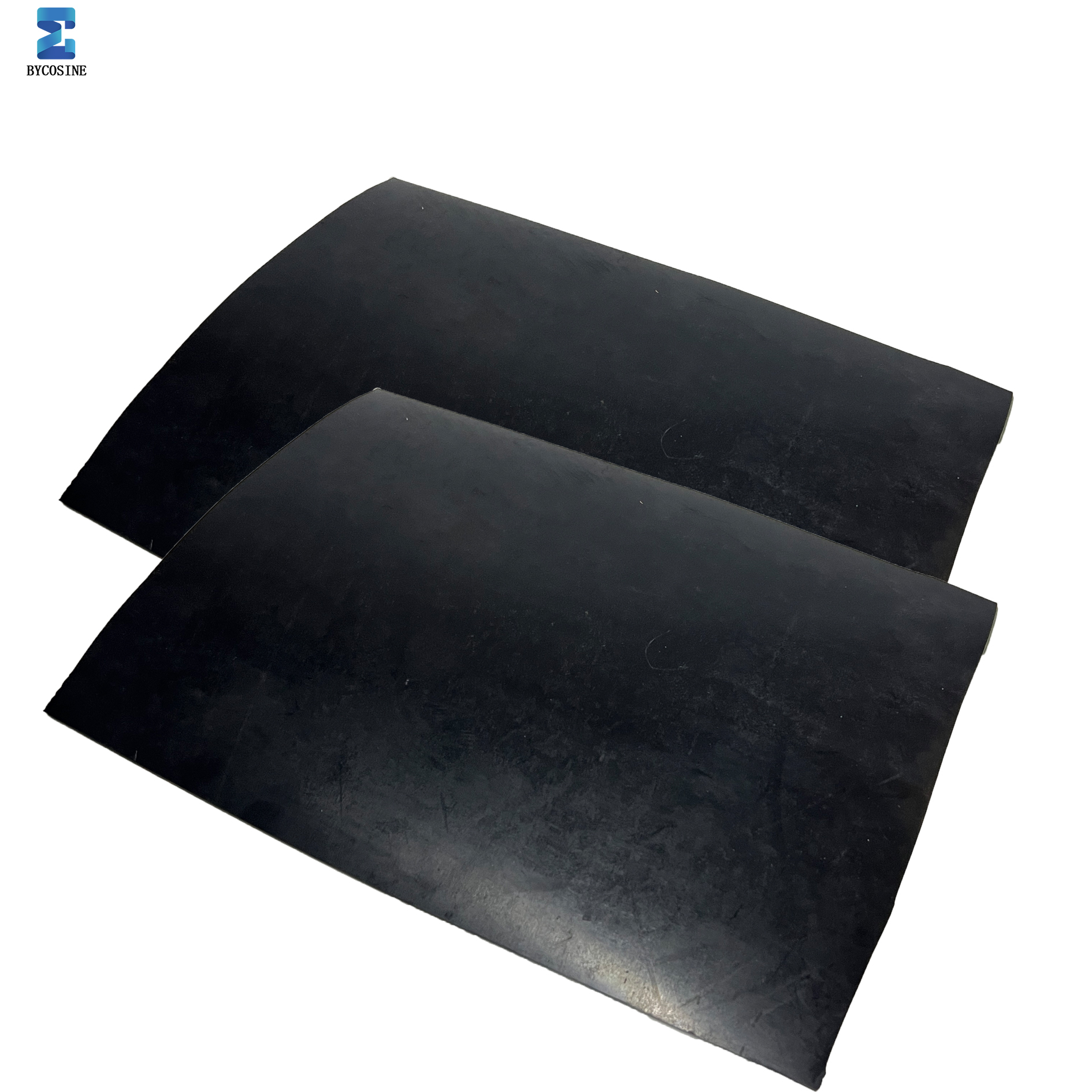

KN373 is a high-performance two-component adhesive with numerous outstanding features. Its bonding strength is extremely remarkable, far exceeding the German DIN industrial standard and even comparable to that of traditional hot vulcanization. This means that in practical applications, it can firmly fix rubber onto the drum surface, forming a reliable wear-resistant and anti-slip protective layer, significantly enhancing the drum's durability. For example, in places with large material transportation volumes such as mines and ports, drums lined with KN373 can operate stably for an extended period, reducing equipment failures caused by rubber lining detachment.

II. Rapid Curing at Room Temperature Improves Work Efficiency

Unlike traditional hot vulcanization adhesives that require heating equipment and a long curing time, the KN373 cold vulcanization adhesive can cure rapidly at room temperature. It generally achieves initial curing in about 30 minutes, reaches usable strength within 2 - 4 hours, and fully cures in 24 hours. This feature is particularly advantageous during emergency repairs, as it can significantly shorten equipment downtime and reduce economic losses. It is especially suitable for harsh environments with high requirements for repair timeliness, such as underground coal mines.

III. Wide Applicability

The KN373 adhesive has broad applicability. It is not only suitable for rubber lining of various drums but also for sealing conveyor belt joints and bonding various rubber gasket materials. It can easily handle bonding between metal and rubber, rubber and rubber, or fabric and rubber. It can withstand an operating temperature of up to 80°C and has flame-retardant properties, ensuring safe use in both above-ground and underground working environments.

IV. Simple and Easy to Use

Using the KN373 cold vulcanization adhesive does not require complex equipment, and it has low requirements for the professional skills of construction personnel. Simply mix the two components of the adhesive evenly in the specified proportion, apply it evenly to the surface to be bonded with a brush or scraper, and press appropriately after 贴合 to expel air bubbles. This simplifies the construction process and reduces costs.

In conclusion, with its excellent bonding strength, rapid curing characteristics, wide applicability, and simple operation, the KN373 cold vulcanization adhesive is an ideal choice for cold glue bonding of drum rubber lining. If you are struggling to choose an adhesive for cold glue bonding of drums, consider trying the KN373 cold vulcanization adhesive. It is sure to deliver satisfactory results.

.jpg)

.png)