What are the functions of electric heating vulcanizers?

2025-06-12 10:35:58The core function of electric heating vulcanizers is to vulcanize conveyor belts. In simple terms, through heating and applying pressure, the rubber material of the conveyor belt undergoes a chemical reaction, becoming tougher and more durable. When the conveyor belt is damaged or needs to be joined, traditional repair methods may not guarantee sufficient strength. However, electric heating vulcanizers can restore the conveyor belt to its original state, or even enhance its performance, through the vulcanization process.

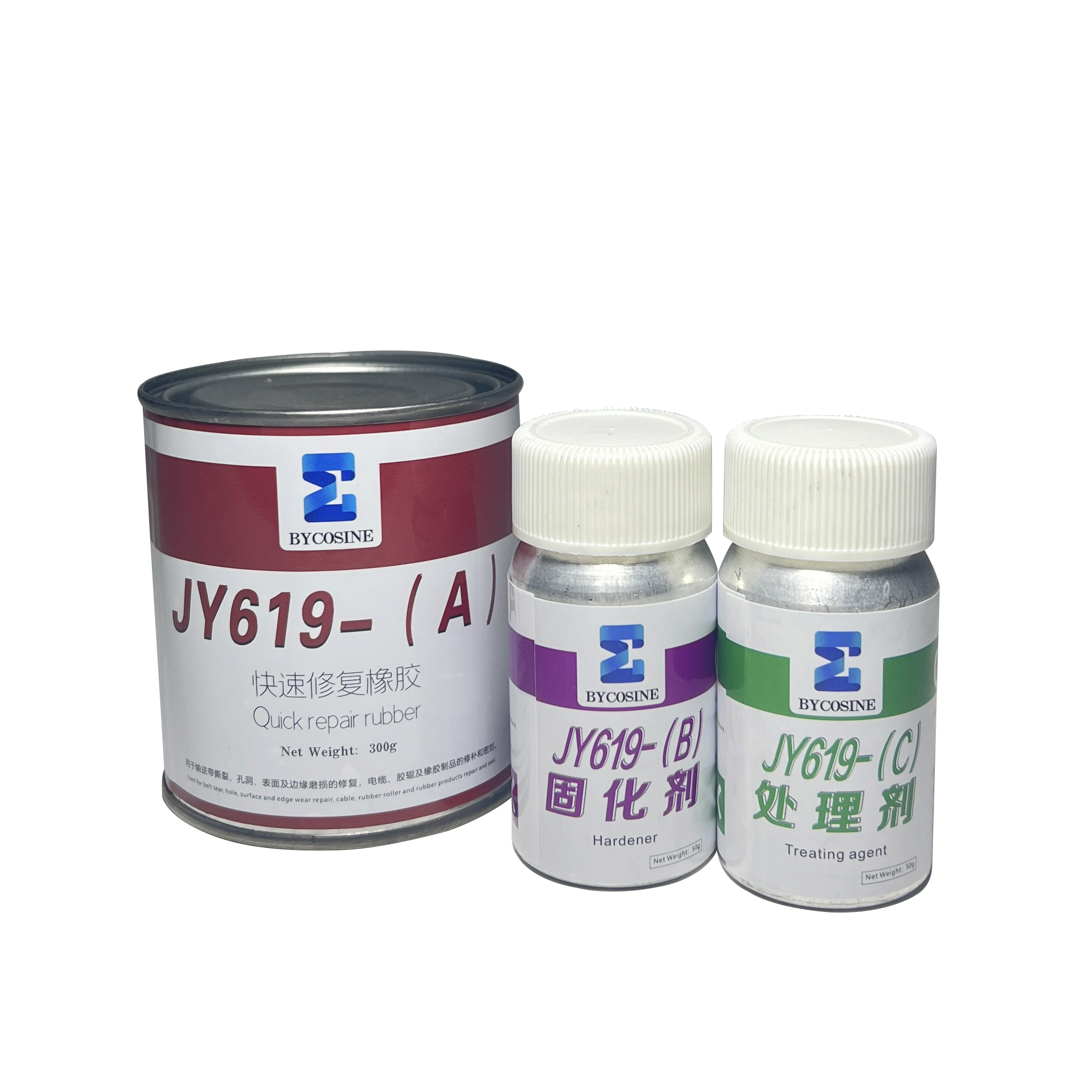

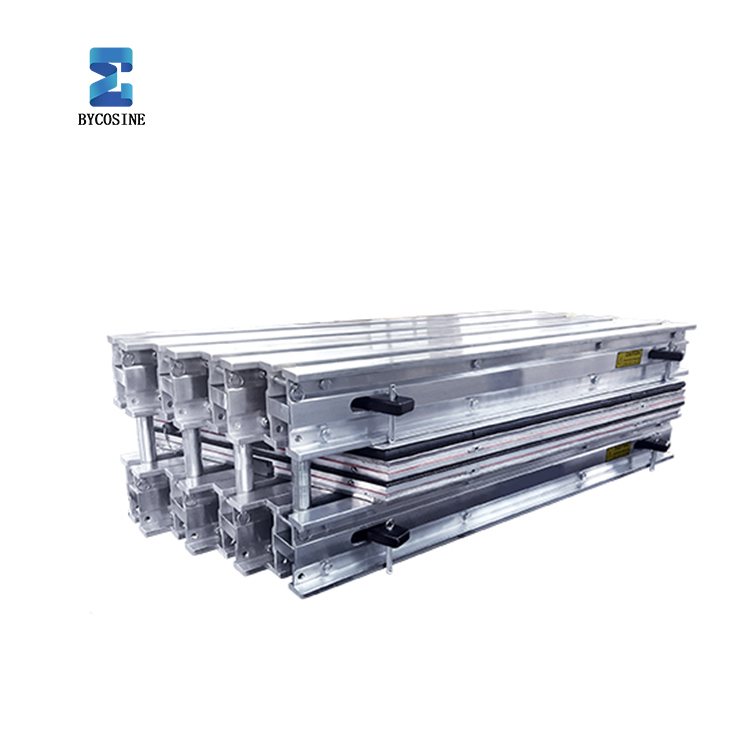

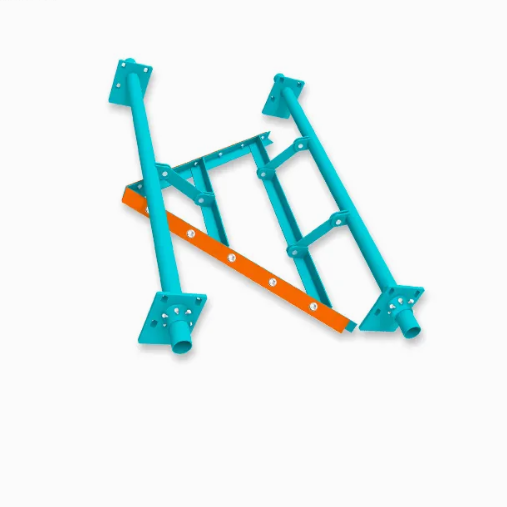

Using an electric heating vulcanizer for conveyor belt vulcanization is not a complicated operation. First, clean the damaged or connecting parts of the conveyor belt thoroughly. Then, place components such as the heating plates and insulation plates of the vulcanizer properly, put the conveyor belt accurately into the vulcanizer, set appropriate temperature and pressure parameters, and start the equipment. After a certain period, the vulcanization is completed, and the strength and stability of the conveyor belt are significantly improved.

This type of vulcanizer has obvious advantages. It provides uniform heating, ensuring consistent vulcanization results across all parts of the conveyor belt. Moreover, the temperature and pressure can be precisely controlled, making it suitable for conveyor belts of different materials and specifications. For these reasons, it is widely used in places where a large number of conveyor belts are required, such as mines, ports, and power plants. Whether it is coal transportation, ore handling, or cargo loading and unloading, electric heating vulcanizers can ensure the stable operation of conveyor belts, reduce downtime due to malfunctions, and improve production efficiency.

In conclusion, electric heating vulcanizers are reliable assistants for maintaining the performance of conveyor belts and ensuring the smooth operation of industrial production, occupying an important position in modern industry.

.jpg)

.png)