The Application of Hot Vulcanization Adhesive DG668 in Conveyor Belt Joints

2025-06-12 10:29:52The Application of Hot Vulcanization Adhesive DG668 in Conveyor Belt Joints

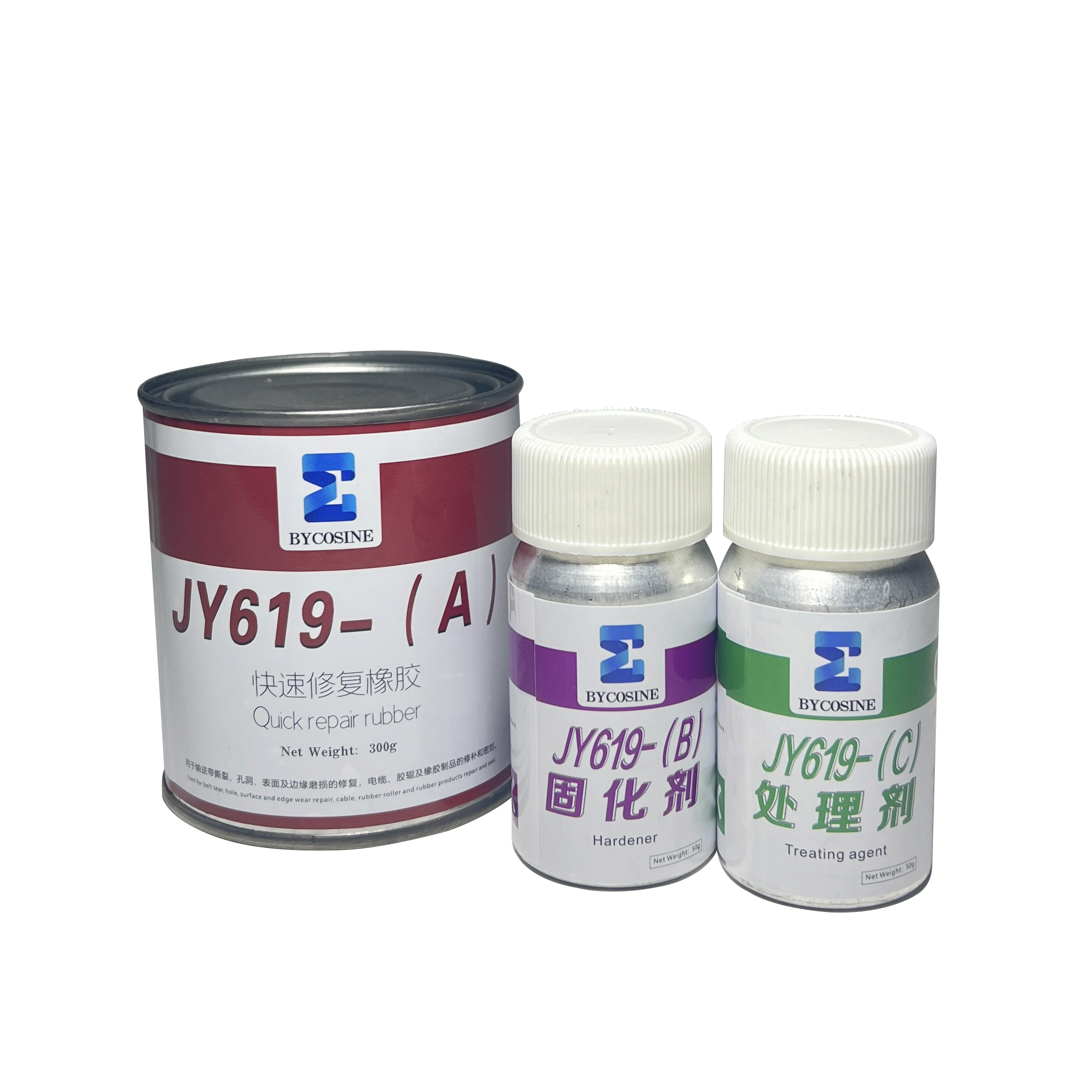

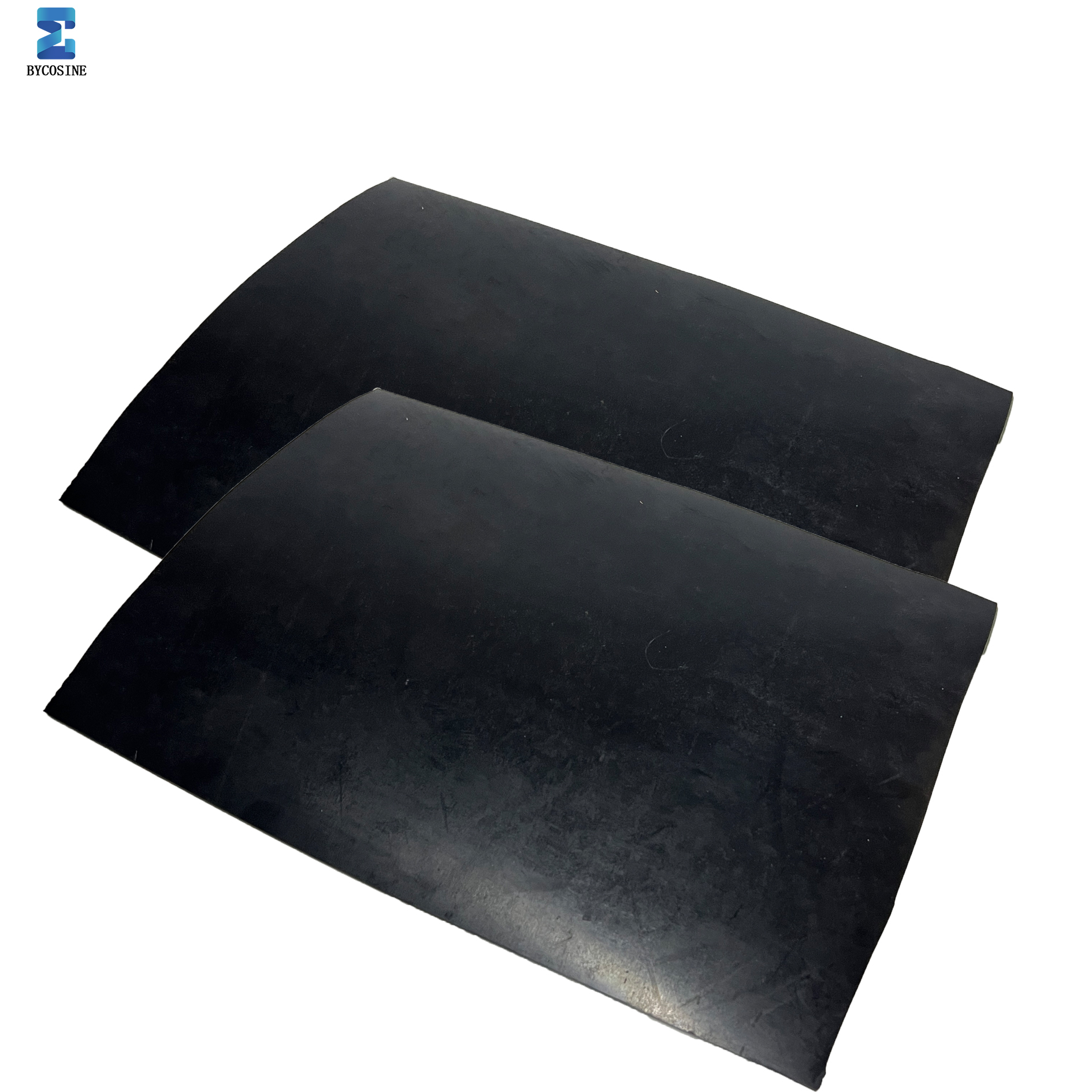

DG668 features high-strength adhesion, enabling tight bonding of conveyor belt joints and significantly reducing the risk of fracture at the joint. Meanwhile, it exhibits excellent high-temperature and wear resistance. Even under harsh working conditions with high temperatures and friction, it ensures long-term stability of the joint and extends the service life of the conveyor belt.

Application of Hot Vulcanization Adhesive DG668 for Conveyor Belt Joints

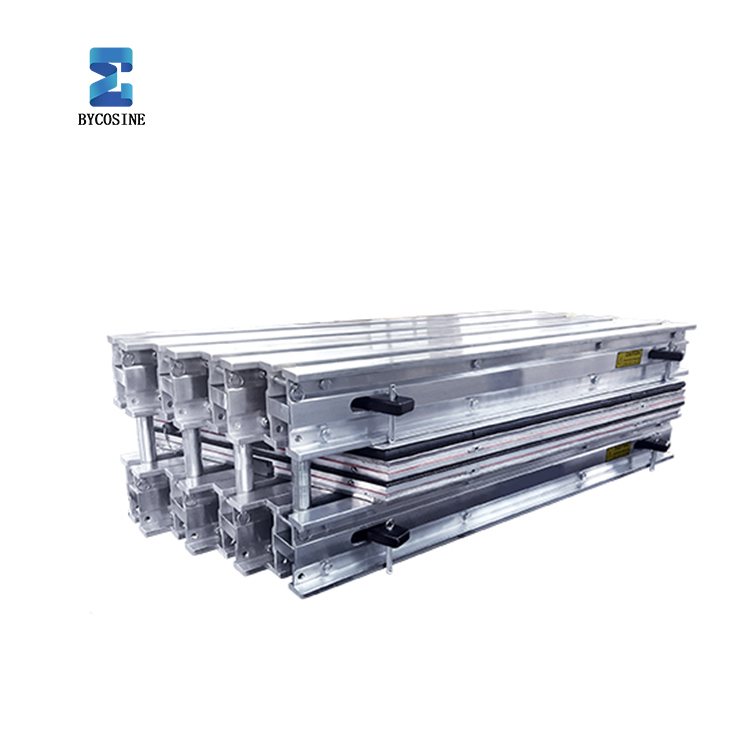

Bonding conveyor belt joints with DG668 is not complicated. First, grind the joint area of the conveyor belt to remove impurities and oil, ensuring the surface is rough. Then, apply DG668 evenly to ensure full coverage. Next, align the joint precisely, use vulcanization equipment to apply appropriate temperature and pressure, and after a period of vulcanization reaction, a firm joint is obtained.

In practical applications, the effect of DG668 is remarkable. After a mining enterprise used DG668 to treat conveyor belt joints, the fracture frequency at the joints was significantly reduced, the number of equipment shutdowns for maintenance decreased, and production efficiency was significantly improved. For enterprises, choosing the hot vulcanization adhesive DG668 to treat conveyor belt joints can not only ensure production continuity but also reduce maintenance costs, making it a reliable solution to improve industrial transportation efficiency.

.jpg)

.png)