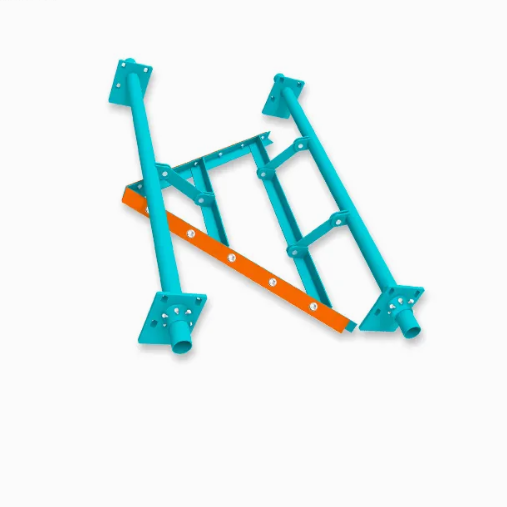

On-site Construction Process for Belt Drum Rubber Coating

2025-06-11 11:11:01Rubber coating of belt drums can enhance friction, reduce wear, and extend the service life of drums. Among them, cold-bonded drum rubber coating is easy to operate, and the following introduces its on-site construction process.

Construction Preparation

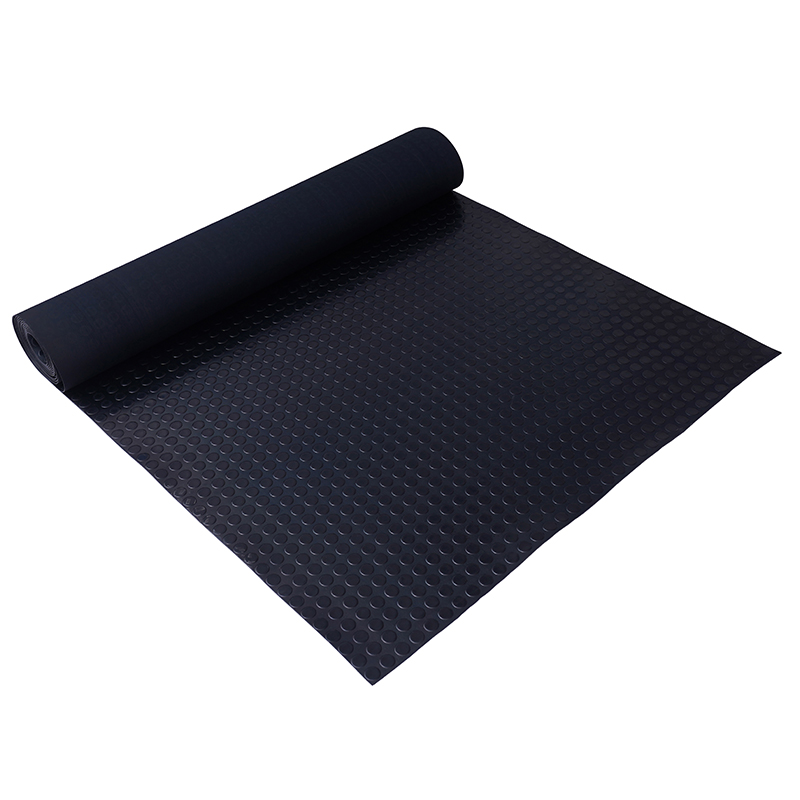

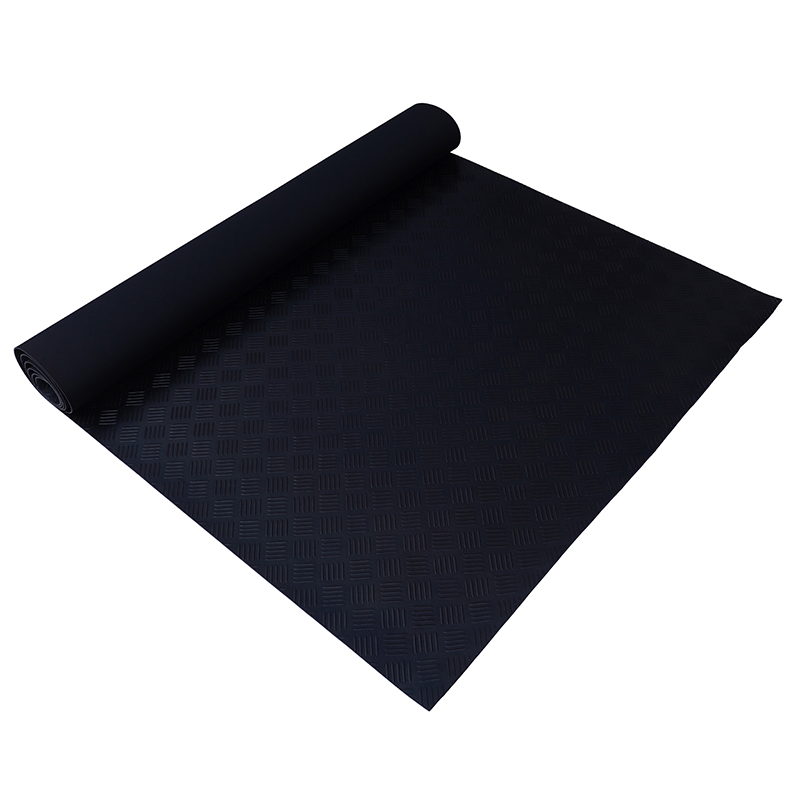

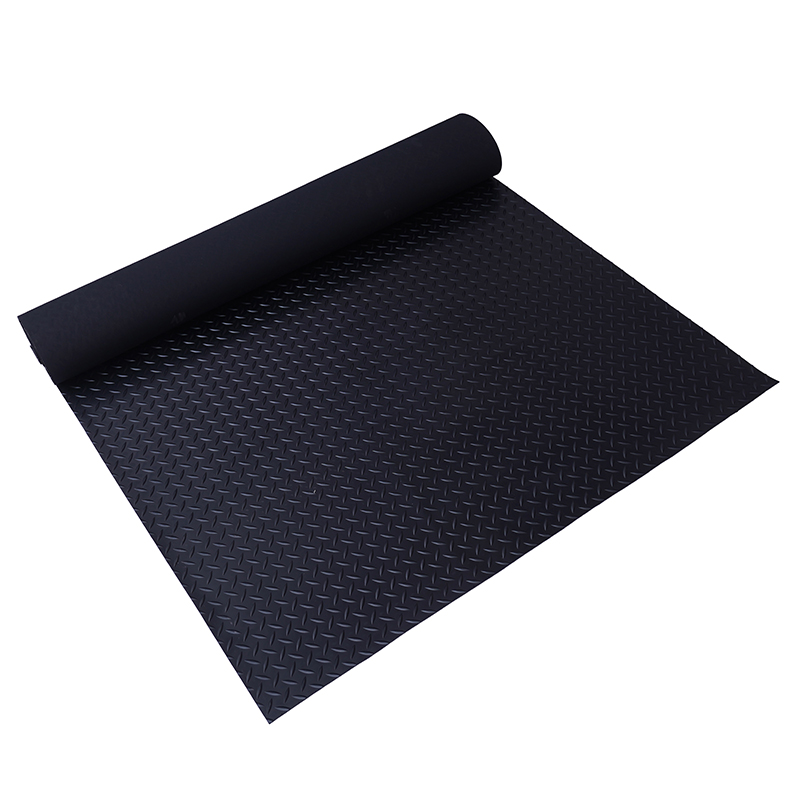

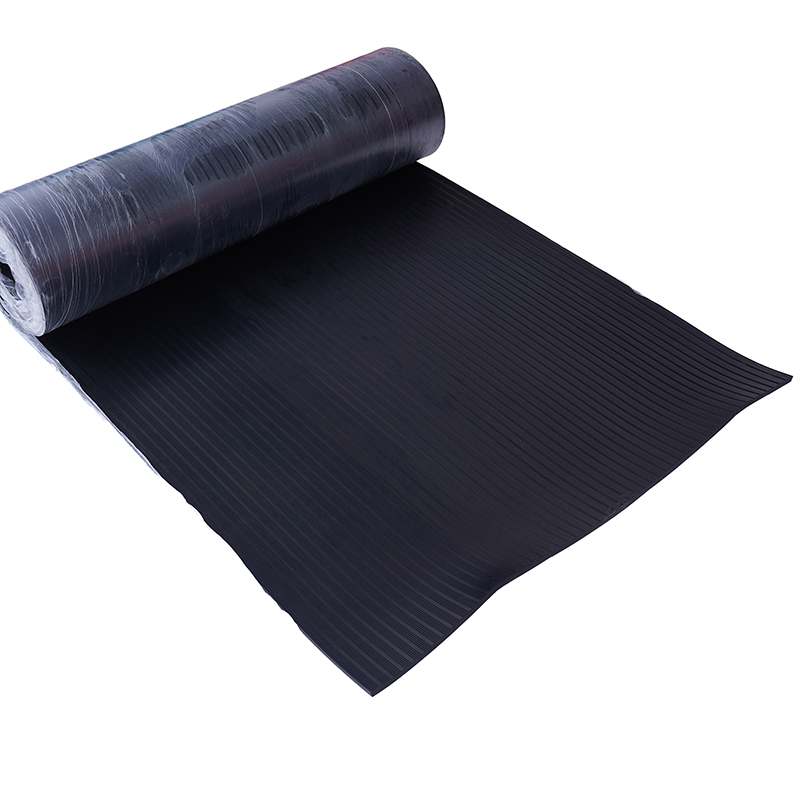

Before construction, prepare tools such as cold-bonded adhesives, cleaners, grinders, angle grinders, and rubber plates that meet specifications. Meanwhile, ensure good ventilation and sufficient lighting at the construction site to create a safe and suitable environment for construction.

Surface Treatment

Use an angle grinder with a wire brush to grind the drum surface, removing oil stains, rust, and impurities to roughen the surface and enhance the adhesion between the rubber plate and the drum. After grinding, thoroughly clean the drum surface with a cleaner to ensure no residue.

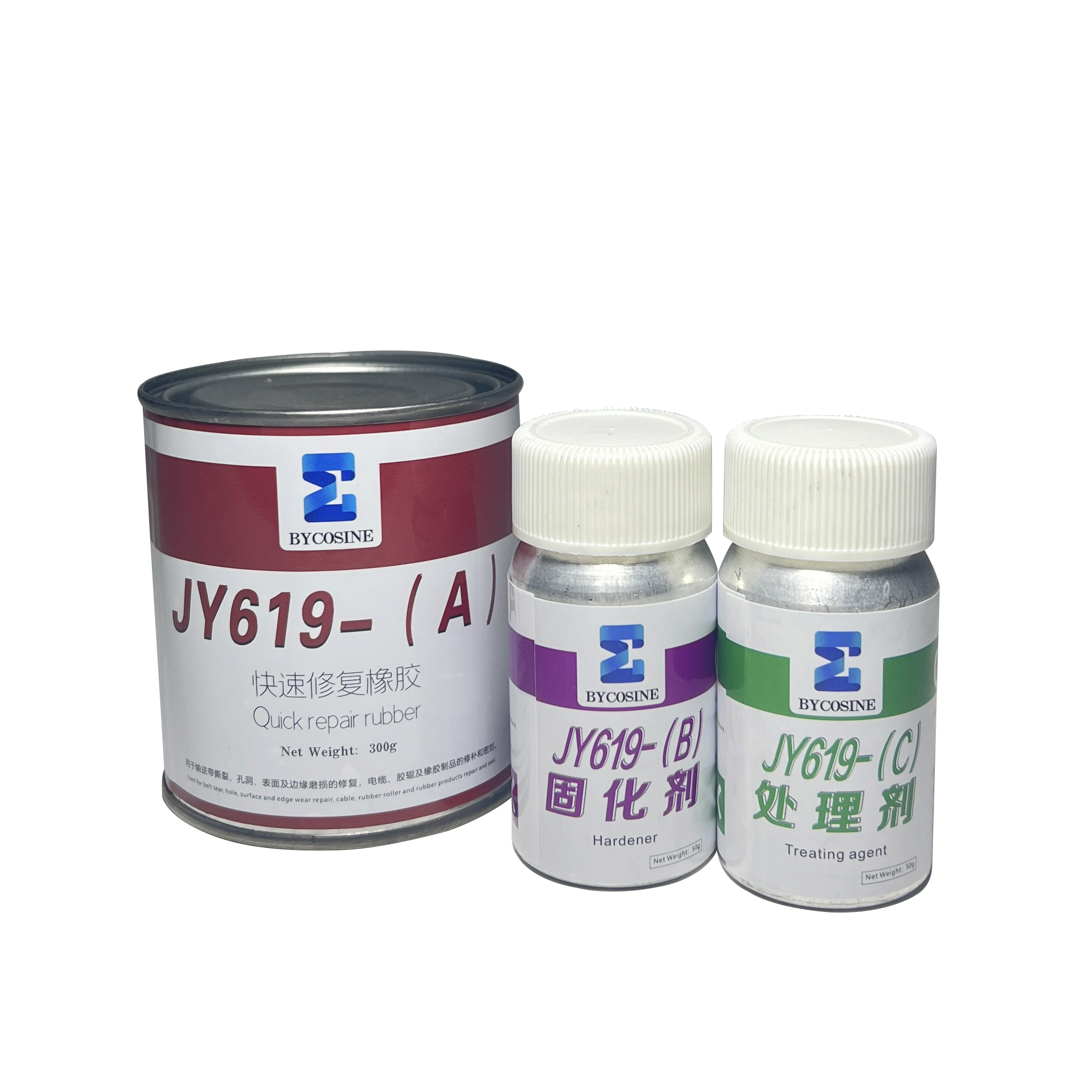

Glue Application

After the drum surface dries, evenly apply a layer of cold-bonded adhesive to both the drum surface and the back of the rubber plate. The glue should be applied uniformly to avoid missing areas or accumulation. After application, wait for the glue to air-dry naturally until it is non-sticky to the touch.

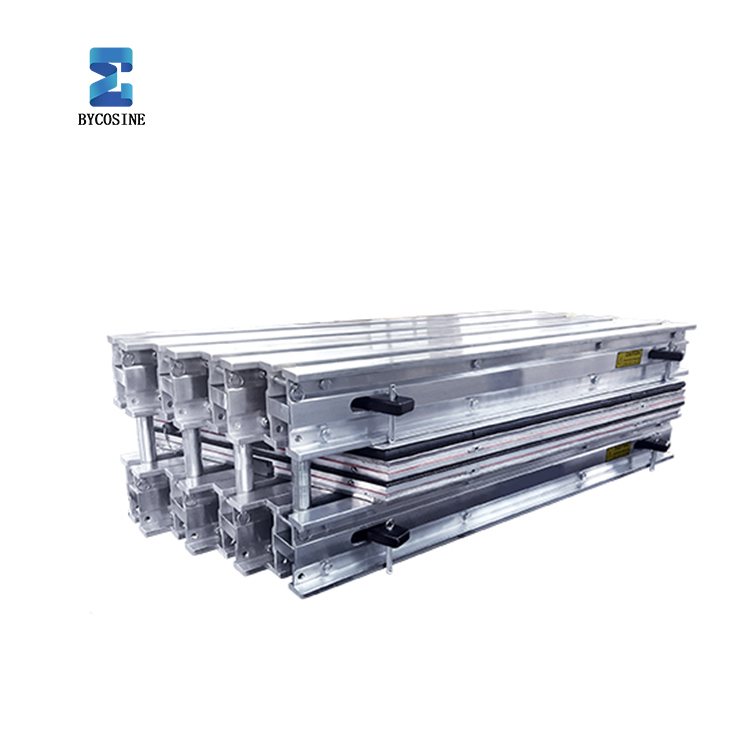

Rubber Plate Bonding

Align the dried rubber plate with the drum, start bonding gradually from one end, and use a pressure roller to compact it while bonding to expel air between the rubber plate and the drum, ensuring a tight fit. During the bonding process, ensure the rubber plate is accurately positioned and the joints are tightly connected.

Joint Treatment

After the rubber plate is bonded, treat the joints. Fill the joints with a special rubber strip, then fix the rubber strip with cold-bonded adhesive to ensure the joints are flat and firm, preventing problems such as edge curling or debonding.

Inspection and Acceptance

After construction, comprehensively inspect the coating effect, checking whether the rubber plate is firmly bonded, the surface is flat, and the joints are well-treated. After confirming no issues, the belt drum can be put into use.

The above is the construction process for cold-bonded rubber coating of belt drums. If you want to learn more about precautions during construction, feel free to ask me.

.jpg)

.png)