Recommendation for Belt Drum Rubber Coating Plates

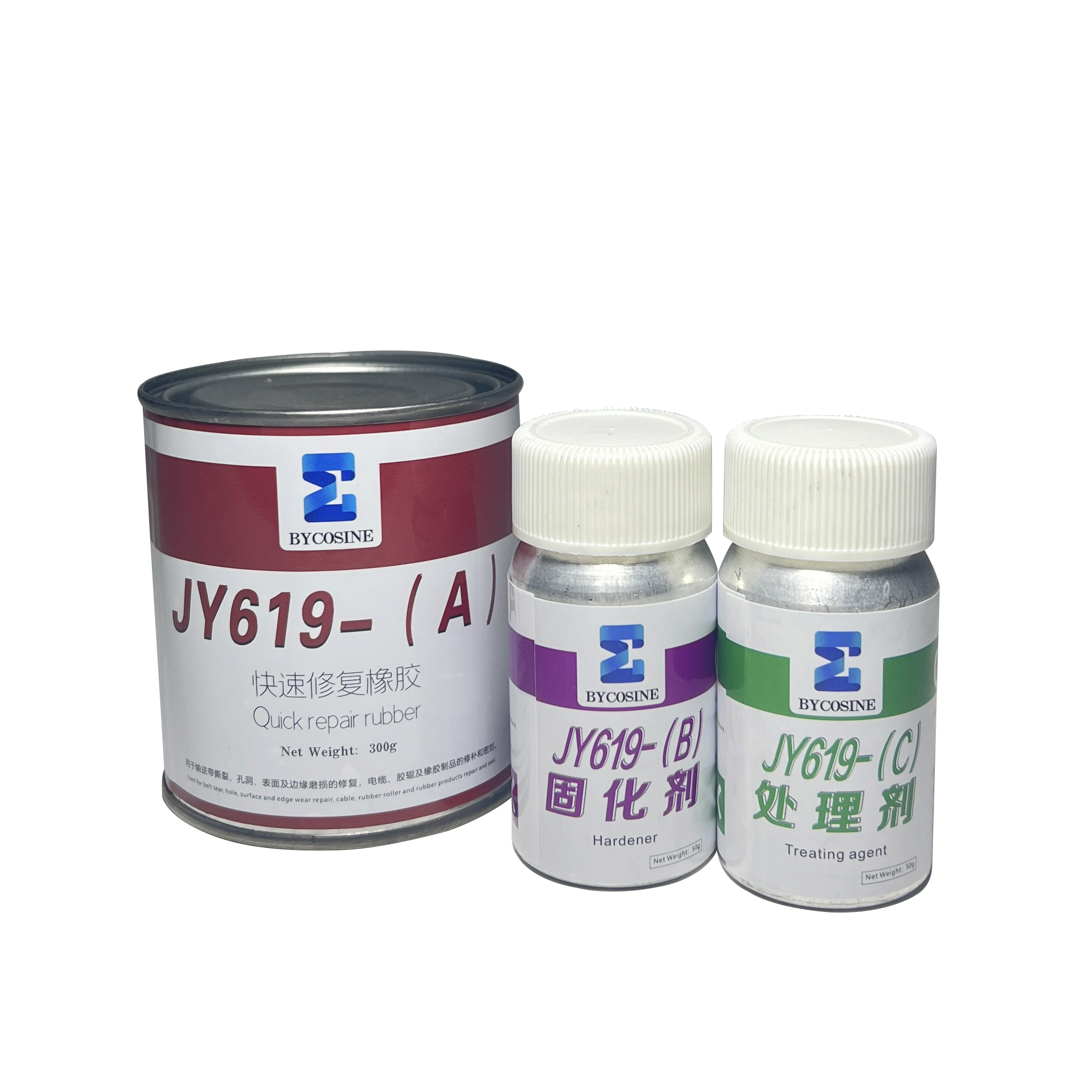

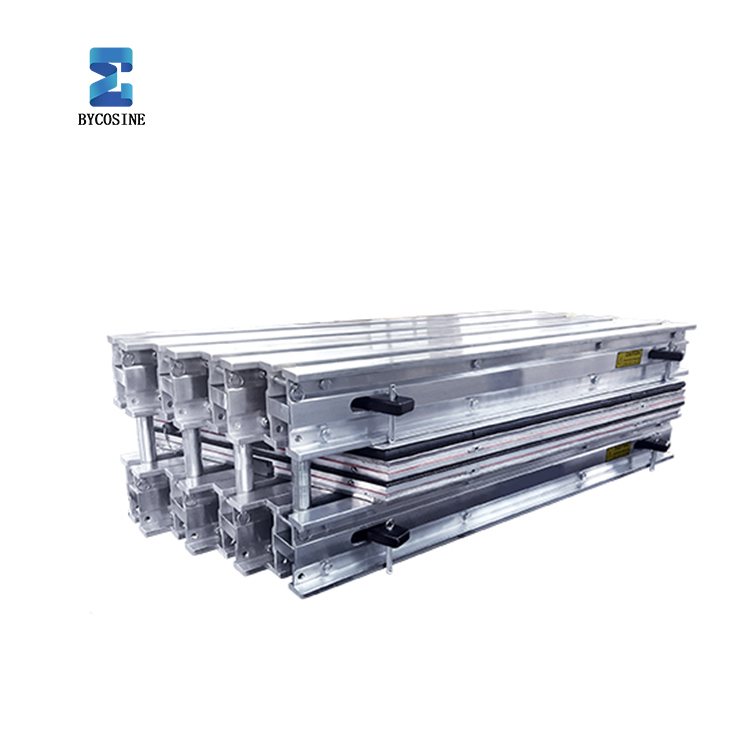

2025-06-11 11:04:05Choosing the right belt drum rubber coating plate can effectively protect the drum and extend its service life. Commonly used cold-bonded rubber plates for drum coating include flat wear-resistant, diamond-patterned wear-resistant, and ceramic wear-resistant rubber plates. Below is a detailed introduction.

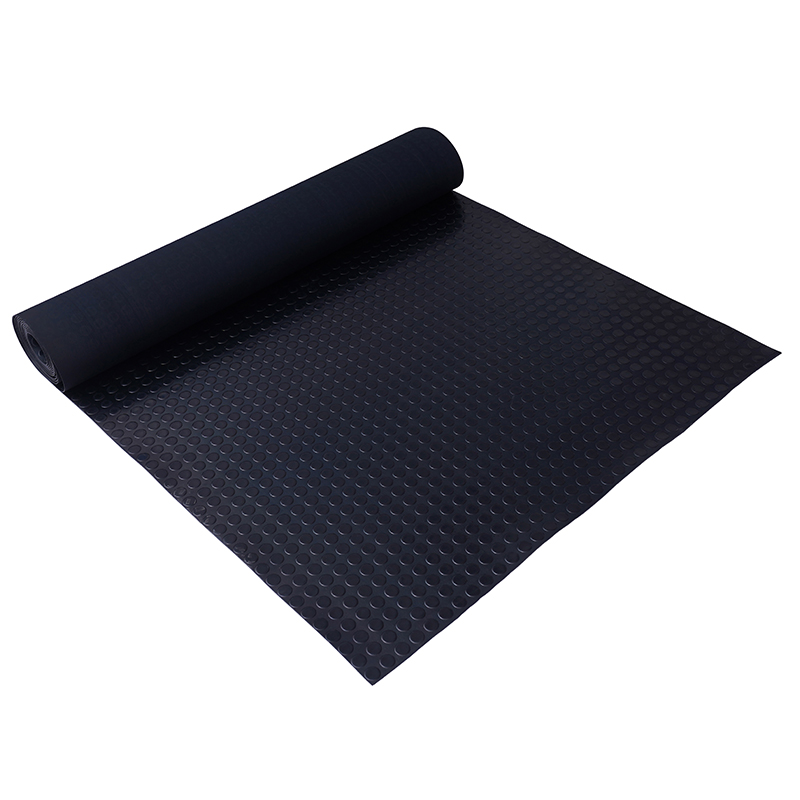

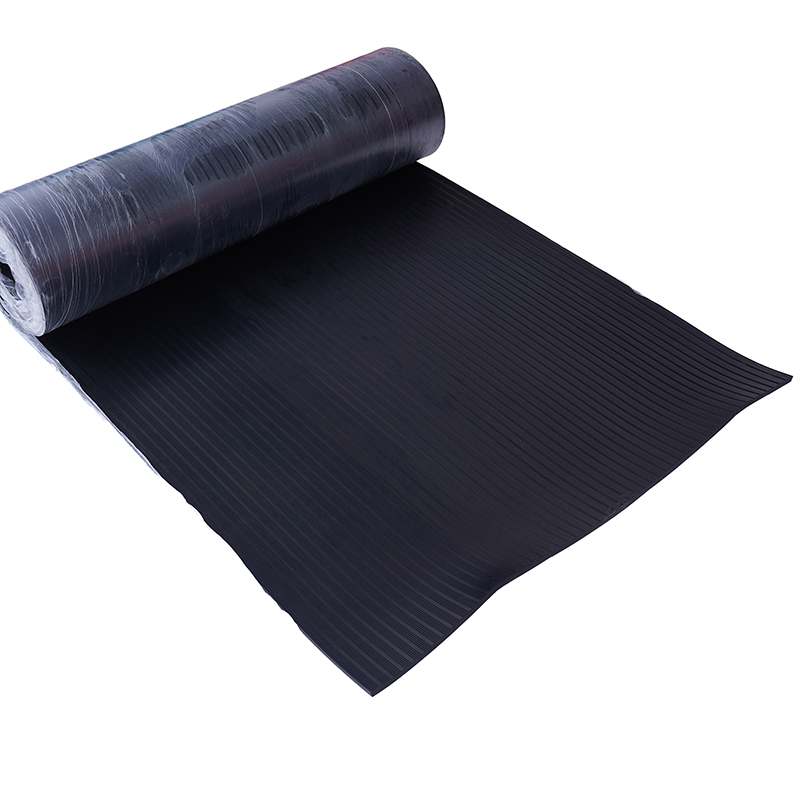

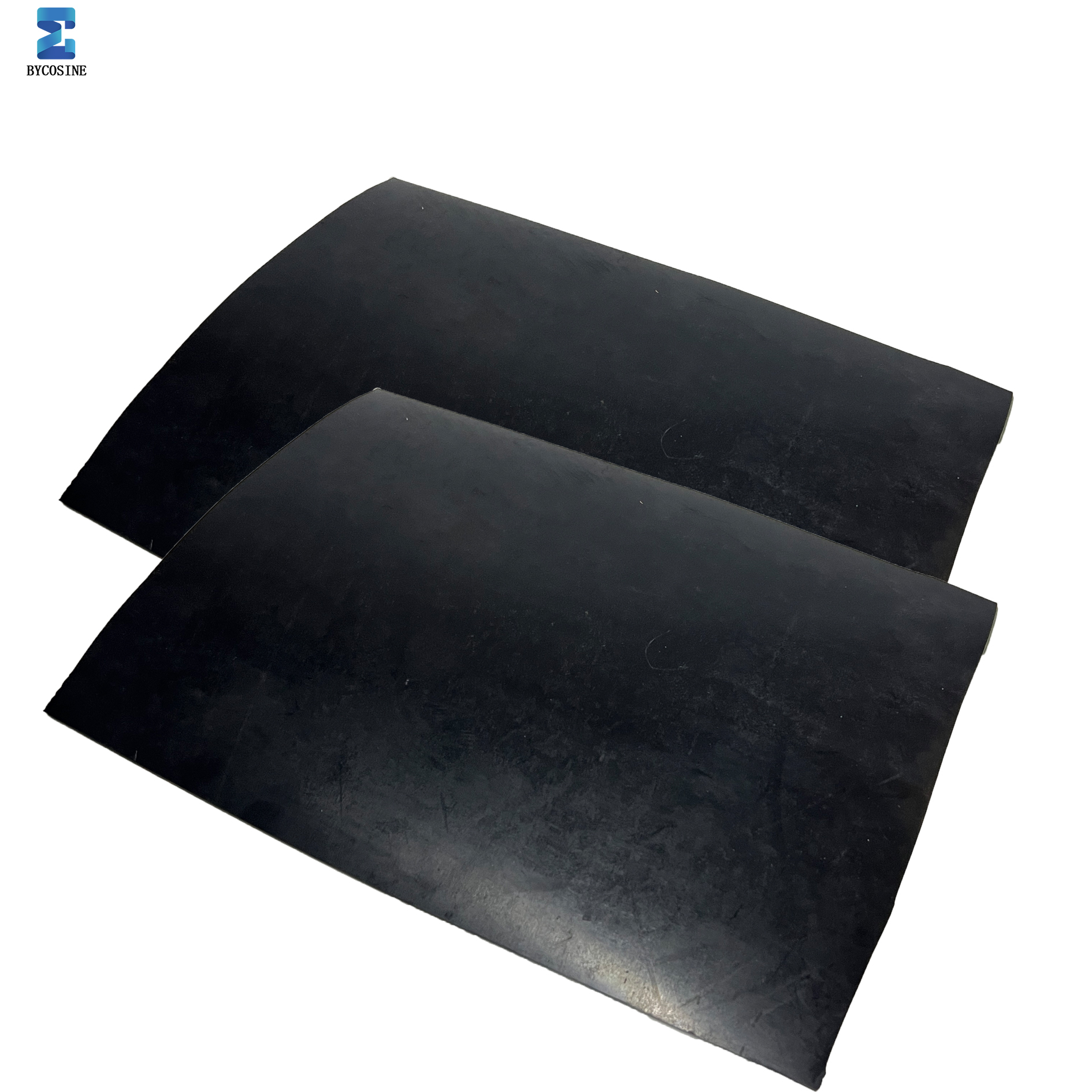

Flat Wear-Resistant Rubber Plate

The flat wear-resistant rubber plate features a smooth surface, soft texture, and excellent elasticity and sealing performance. It is relatively low in cost and easy to install, suitable for conveying scenarios with stable environments and minimal material impact, such as the transportation of grains and light industrial products. However, due to the lack of surface patterns, its friction is relatively small, making it prone to slipping on drums under heavy loads or high-speed operation.

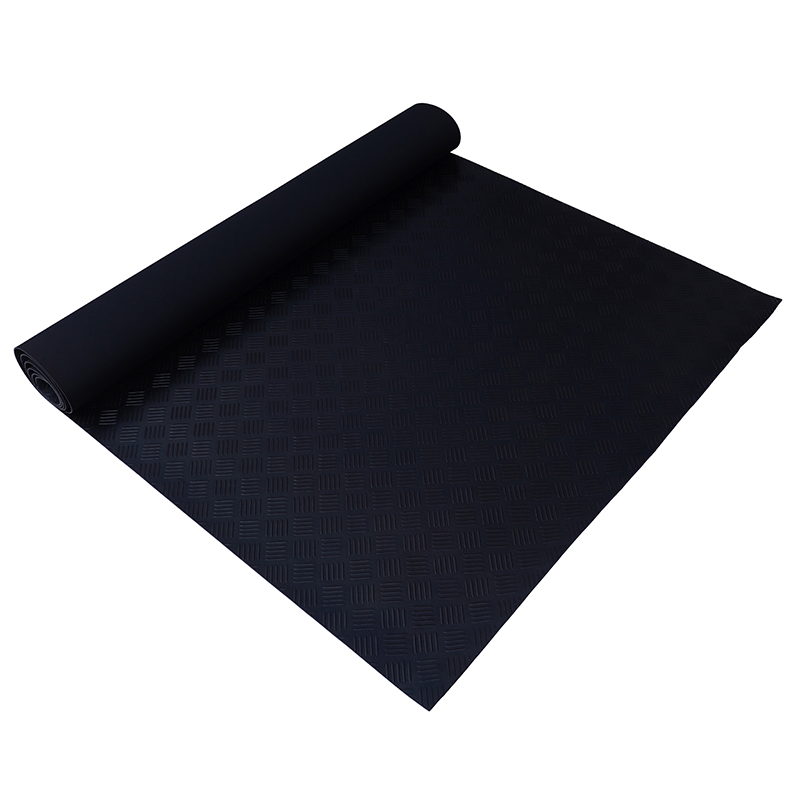

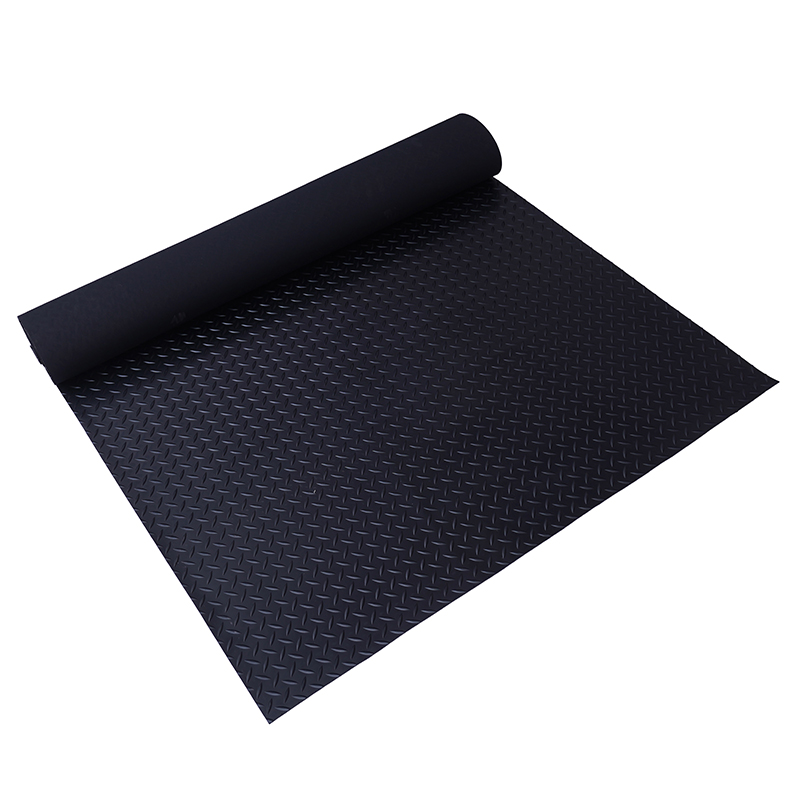

Diamond-Patterned Wear-Resistant Rubber Plate

The diamond-patterned wear-resistant rubber plate has diamond-shaped patterns on its surface, which significantly increases the friction between the rubber plate and the belt, effectively preventing slipping. Meanwhile, the diamond patterns can disperse the impact of materials on the drum, enhancing wear resistance. It is suitable for harsh environments with large material transportation volumes, such as mines and coal industries. Additionally, its unique pattern design has a certain drainage and slag discharge function, avoiding material accumulation that may affect conveying efficiency.

Ceramic Wear-Resistant Rubber Plate

The ceramic wear-resistant rubber plate combines the high wear resistance of ceramics with the flexibility of rubber, boasting the strongest wear resistance among the three types. The ceramic tiles embedded in the surface have extremely high hardness, capable of withstanding strong abrasion and high impact forces, commonly used in high-wear working conditions like stone plants and steel mills. However, it comes with a higher price and more complex installation processes.

Each rubber plate has its advantages and disadvantages. Choosing based on actual conveying needs and working conditions can provide the best protection for the drum. If you want to learn more about the installation key points of different rubber plates, feel free to ask me.

.jpg)

.png)