Which Cold-Bonding Adhesive for Drum Rubber Coating is Better? Recommended: KN373 Cold Vulcanization Adhesive

2025-06-09 11:00:17In industrial production, drum rubber coating plays a critical role in enhancing the wear resistance, corrosion resistance, and friction of drums. As the core material for drum rubber coating, the quality of cold-bonding adhesives directly determines the coating effect and the service life of the drum. Among the many cold-bonding adhesives on the market, which one stands out? We strongly recommend Pecson KN373 Cold Vulcanization Adhesive.

I. Outstanding Advantages of KN373 Cold Vulcanization Adhesive

1. Ultra-Strong Bonding Strength

KN373 uses a two-component cold vulcanization technology that achieves molecular-level bonding between the rubber plate and the drum's metal surface through chemical bonding. Its bonding strength far exceeds the German DIN industrial standard and can even compare with hot vulcanization processes. In high-intensity operation scenarios such as port coal loading and unloading, it can successfully withstand the direct impact of large ore blocks, significantly extending the rubber plate replacement cycle.

2. Excellent Flexibility and Impact Resistance

The cured bonding layer is both rigid and flexible, capable of buffering material impacts and handling drum vibrations. In tests on a mining crusher conveying system, the edges of rubber plates using KN373 could withstand impacts from 50mm-diameter ore, with a service life more than twice that of ordinary rubber plates.

3. Resistance to High Temperature and Humidity

It maintains excellent peel resistance even in environments with temperatures up to 80°C or high humidity. Field tests in a cement plant's clinker conveying system showed that drums coated with KN373 operated continuously for over 12 months without rubber plate detachment.

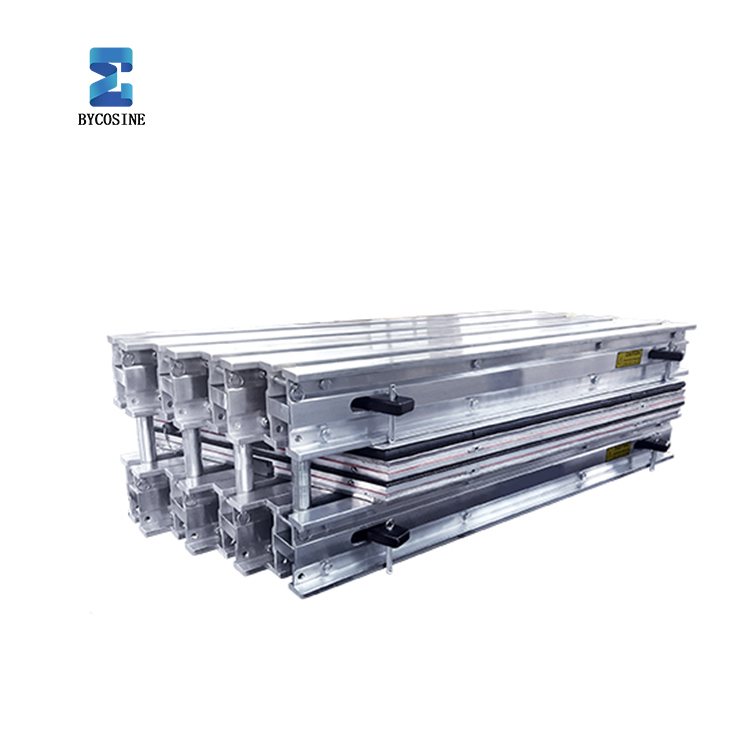

4. Convenient and Efficient Construction

It only takes 30 minutes for initial curing and reaches usable strength within 2-4 hours, supporting room-temperature curing. This makes it particularly suitable for flammable and explosive environments such as coal mine shafts. For example, in an underground repair at an iron ore dressing plant, a drum using KN373 was installed and put into use within 8 hours, reducing downtime by 70% compared to traditional processes.

II. Wide Range of Applications

1. Mining Industry

In large open-pit coal mines, conveyor belts face extreme temperature differences from -20°C to 50°C for long periods. After using KN373 for rubber coating, the drum rubber plates showed no brittle cracking at low temperatures or softening deformation at high temperatures, with an annual failure rate reduced by 90%.

2. Cement Industry

For the severe wear conditions of clinker conveying systems, the heat resistance of KN373 ensures that rubber plates do not soften or detach, reducing failure downtime by 80%. A single production line can save over 2 million yuan in maintenance costs annually.

3. Port Logistics

During coal loading and unloading, the impact resistance of KN373 withstood the test of an average daily handling of 50,000 tons of materials. The wear of rubber plates was reduced by 65% compared to the previous generation product, and the Overall Equipment Effectiveness (OEE) increased by 18%.

III. Precautions for Using KN373

1. Metal Treatment Agent Enhancement

Applying BD836 metal treatment agent can enhance the adhesive's wettability, increasing bonding strength by over 30%.

2. Precise Mixing and Application

Strictly mix the main agent and curing agent at a ratio of A:B = 100:1. Use a brush or scraper to apply an even coating with a thickness of 0.5-1mm to prevent missed spots or accumulation.

3. Curing Environment Control

After curing at room temperature for 24 hours, carefully inspect the bonding surface for air pockets or cracks. Put it into use only after confirming no issues.

With core advantages such as "ultra-strong bonding, weather-resistant and wear-resistant, fast curing," Pecson KN373 Cold Vulcanization Adhesive provides a comprehensive solution for drum rubber coating. Whether facing the extreme challenges of high-cold mining areas or the continuous tests of high-temperature clinker conveying, KN373 ensures stable equipment operation with high quality. For enterprises pursuing cost reduction and efficiency improvement, choosing KN373 means choosing a more efficient and reliable production model.

.png)