Causes of Surface Scratches on Coal Conveyor Belts and Common Repair Methods

2025-06-09 11:07:33Causes of Surface Scratches on Coal Conveyor Belts

Material FactorsSharp stones, metal debris, or other foreign objects mixed in with coal can directly scratch the belt surface during transportation.

Equipment-Related Issues

- Non-rotating idlers or uneven drum surfaces can scrape the belt as it passes through.

- Excessively rigid scraper blades on cleaners or overly tight contact with the belt can also cause scratches.

Improper Installation or OperationExcessive belt tension, for example, can lead to excessive friction between the belt and equipment components during operation, resulting in scratches.

Repair Methods for Surface Scratches on Coal Conveyor Belts

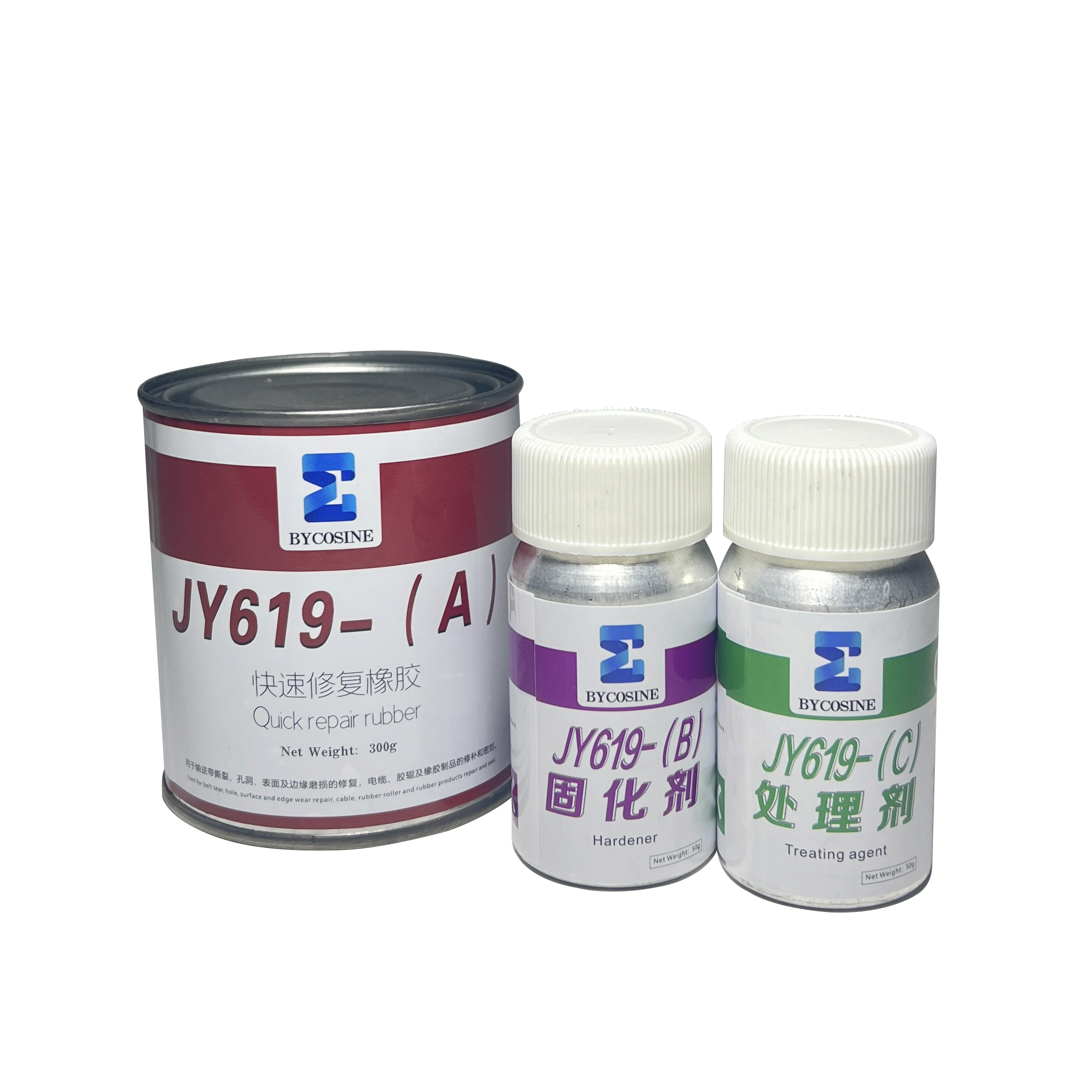

Cold Vulcanization Repair

- Clean the scratched area to remove dust and debris.

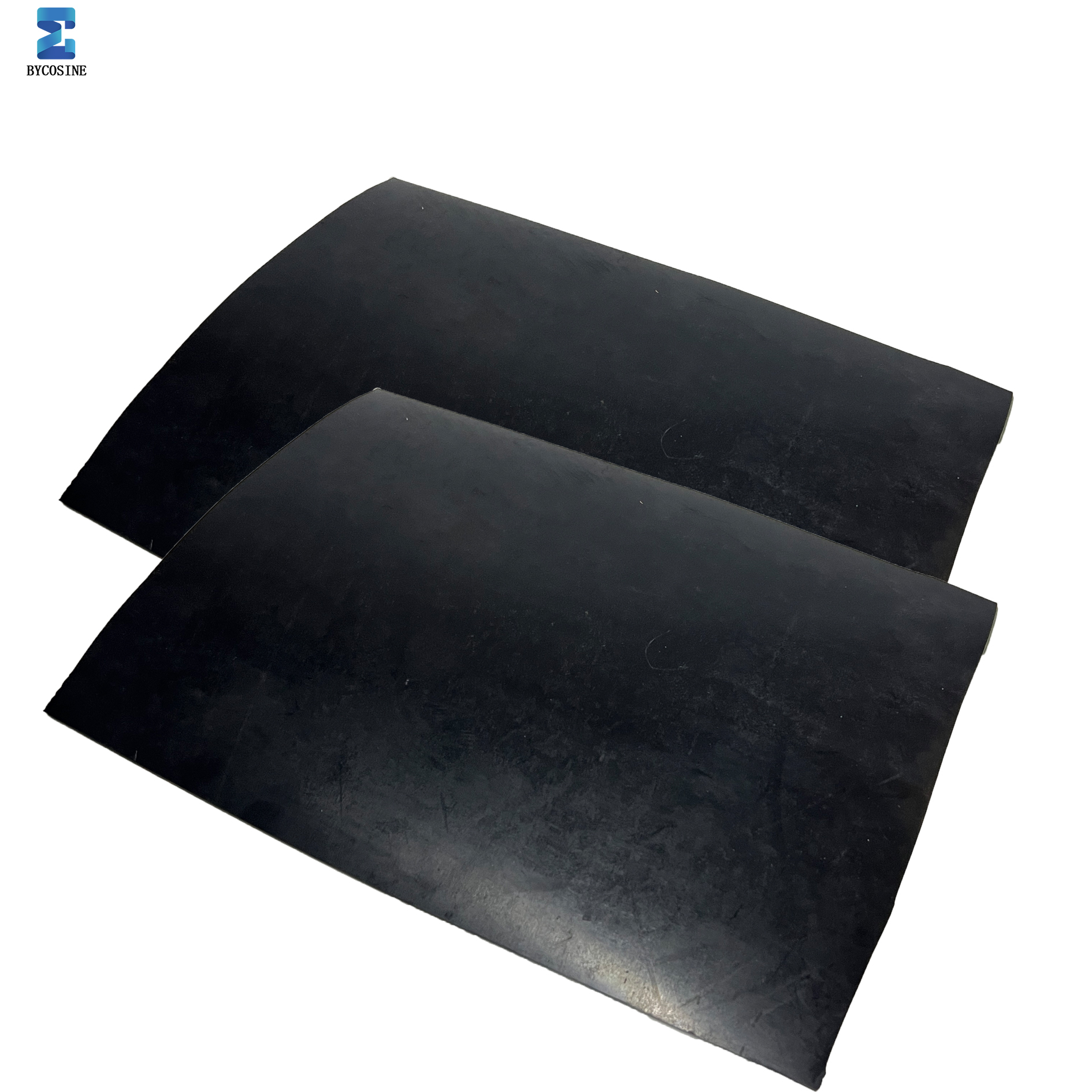

- Apply specialized cold vulcanization adhesive, attach a repair rubber plate, press it firmly, and wait for the adhesive to cure. This method is simple and convenient to operate.

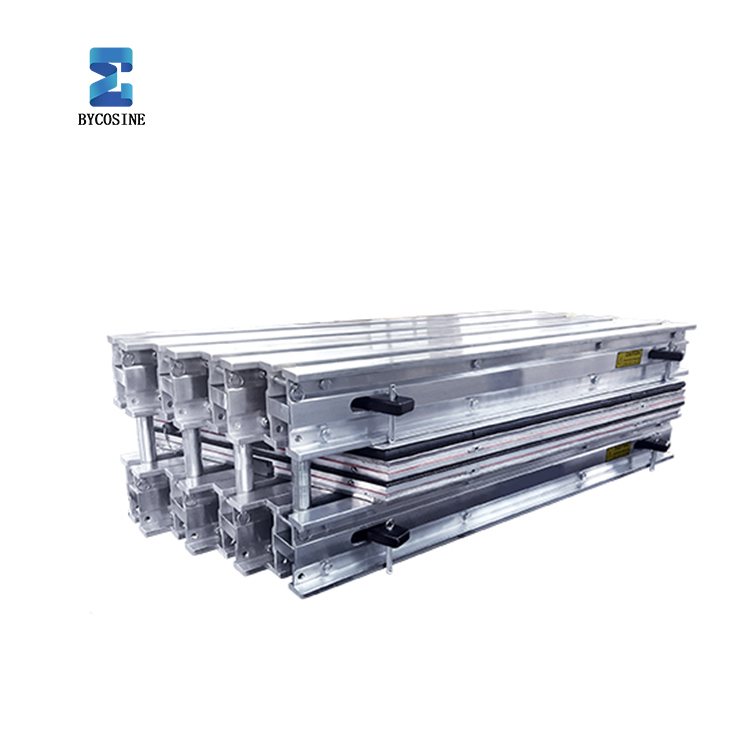

Hot Vulcanization Repair

If the scratch is severe and cannot be repaired by the above methods, the only option is to replace the coal conveyor belt to ensure smooth coal transportation.

- Sand the scratched area to create a rough surface.

- Apply hot vulcanization adhesive, place uncured rubber material, and use a vulcanizer to apply heat and pressure, bonding the rubber material with the belt through vulcanization. This method offers high repair strength and ensures the belt’s normal use.

Understanding the causes of scratches and repair methods for coal conveyor belts allows for timely problem-solving. If you want to learn more about conveyor belt maintenance, feel free to contact me at any time.

.png)